|||||||||||| XH MAR BETHLEHEM

DRYING KILNS

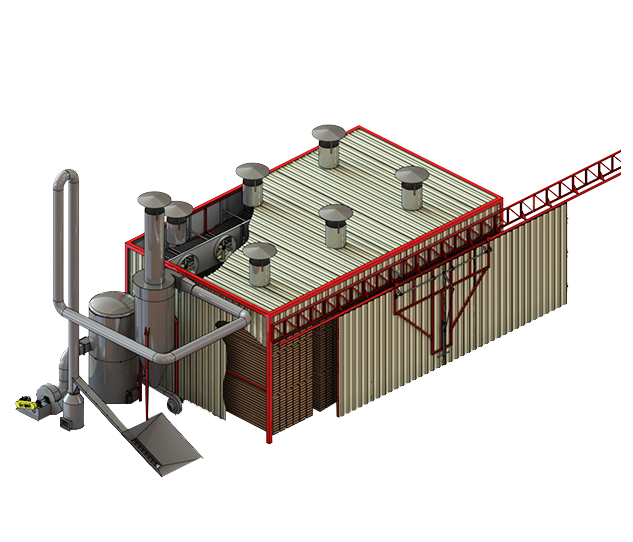

The wood drying kilns from XH MAR BETHLEHEM are carefully developed to carry out the drying of the material, with controlled temperature conditions.

THE IMPORTANCE OF ARTIFICIAL DRYING

Wood usually suffers physical and mechanical alterations due to its moisture content. For this reason, it is necessary to go through a drying process before its use in industrial processes. Drying is considered a very important stage to guarantee a better quality standard and a higher added value to the final product.

If the wood moisture removal is well performed, the industry will benefit from its several advantages and will avoid problems that may damage the raw material.

DRYING KILNS

The wood drying kilns from XH MAR BETHLEHEM are carefully developed to carry out the drying of the material, with controlled temperature conditions.

THE IMPORTANCE OF ARTIFICIAL DRYING

Wood usually suffers physical and mechanical alterations due to its moisture content. For this reason, it is necessary to go through a drying process before its use in industrial processes. Drying is considered a very important stage to guarantee a better quality standard and a higher added value to the final product.

If the wood moisture removal is well performed, the industry will benefit from its several advantages and will avoid problems that may damage the raw material.

|||||||||||| XH MAR BETHLEHEM

ESTUFAS DE SECAGEM

Estufas que oferecem o menor custo de secagem do Brasil. Nossa tecnologia própria possibilita a queima de serragem verde com 60% de umidade e muitas outras vantagens.

A IMPORTÂNCIA DA SECAGEM ARTIFICIAL

A madeira costuma sofrer alterações físicas e mecânicas devido ao seu teor de umidade. Em razão disso, é necessário promover sua secagem antes do seu uso nos processos industriais. A secagem é considerada uma etapa de grande importância para garantir um melhor padrão de qualidade e maior valor agregado ao produto final.

Se a retirada da umidade da madeira for bem executada, a indústria se beneficiará de suas diversas vantagens e evitará problemas que podem danificar a matéria prima.

REQUEST A QUOTE

Our staff is ready to assist you.

BENEFITS OF DRYING

- Improves the material’s thermal and electrical insulation properties and its mechanical and physical properties.

- Reduces the attack of staining fungi.

- Improves the impregnation capacity of paints, glues and preserving substances.

- Prevents twisting, buckling and warping, maintaining the original conditions or the conditions of when the wood was chopped.

- Considerable reduction of the weight of the material, resulting in freights with a larger volume of wood, improving its cost-benefit.

With simplified assembly and transport and modular construction, the XH MAR BETHLEHEM Drying Kilns are self-supporting equipment, dispensing the need for masonry and allowing easy relocation.

BENEFITS OF DRYING

- Improves the material’s thermal and electrical insulation properties and its mechanical and physical properties.

- Reduces the attack of staining fungi.

- Improves the impregnation capacity of paints, glues and preserving substances.

- Prevents twisting, buckling and warping, maintaining the original conditions or the conditions of when the wood was chopped.

- Considerable reduction of the weight of the material, resulting in freights with a larger volume of wood, improving its cost-benefit.

With simplified assembly and transport and modular construction, the XH MAR BETHLEHEM Drying Kilns are self-supporting equipment, dispensing the need for masonry and allowing easy relocation.

REQUEST A QUOTE

Our staff is ready to assist you.

XH MAR DRYING KILNS

LOW PRESSURE STEAM OR HOT WATER DRYING KILN

This kiln is an in-house development with XH MAR BETHLEHEM technology and focuses on generating steam by burning green sawdust with a humidity (water content) of 60%.

STEAM DRYING KILN

This technology is widespread on the market and is suitable for lumber mills that dry high volumes of wood monthly.mensalmente.

CAPACITY

From 20m³ to 150m³ of wood.

FUELS

Chip, firewood, sawdust, sawmill waste, rice hulls, and others.

REQUEST A QUOTE

Our staff is ready to assist you.

REQUEST A QUOTE

Our staff is ready to assist you.

ADRESS

Highway SC 350 | N° 4851 | Downtown | CEP: 89170-000 | Laurentino/SC | Brazil

OFFICE HOURS

Monday to Friday

8:00 a.m. to 11:30 a.m.

1:30 p.m. to 5:30 p.m.

ADRESS

Highway SC 350 | N° 4851 | Downtown | CEP: 89170-000 | Laurentino/SC | Brazil

OFFICE HOURS

Monday to Friday

8:00 a.m. to 11:30 a.m.

1:30 p.m. to 5:30 p.m.